"Just change the board then we can reduce the temperatures to become normal"

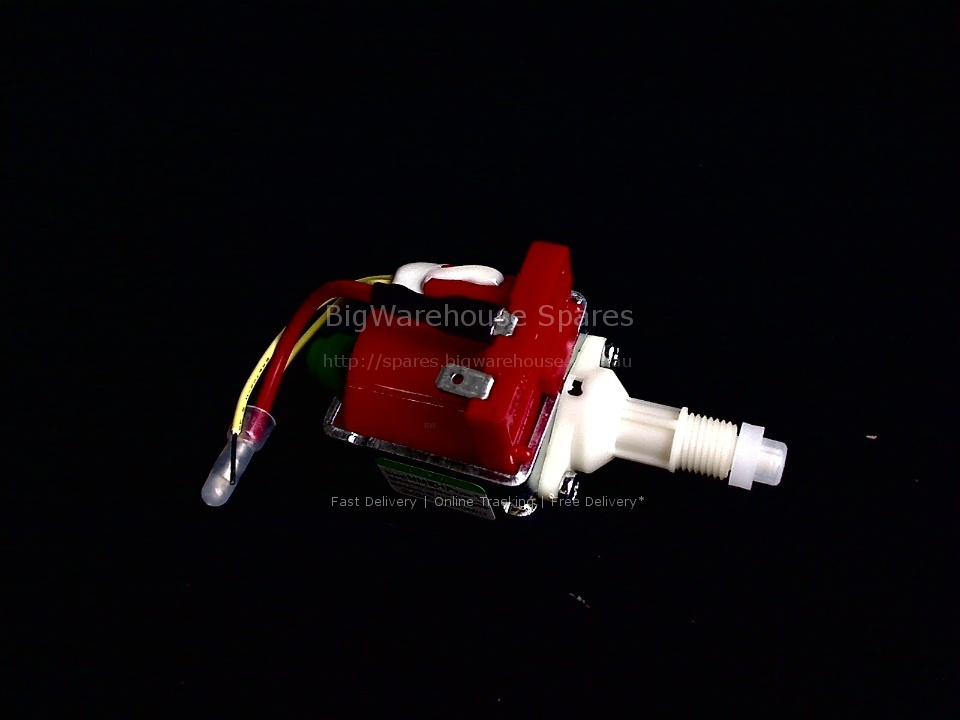

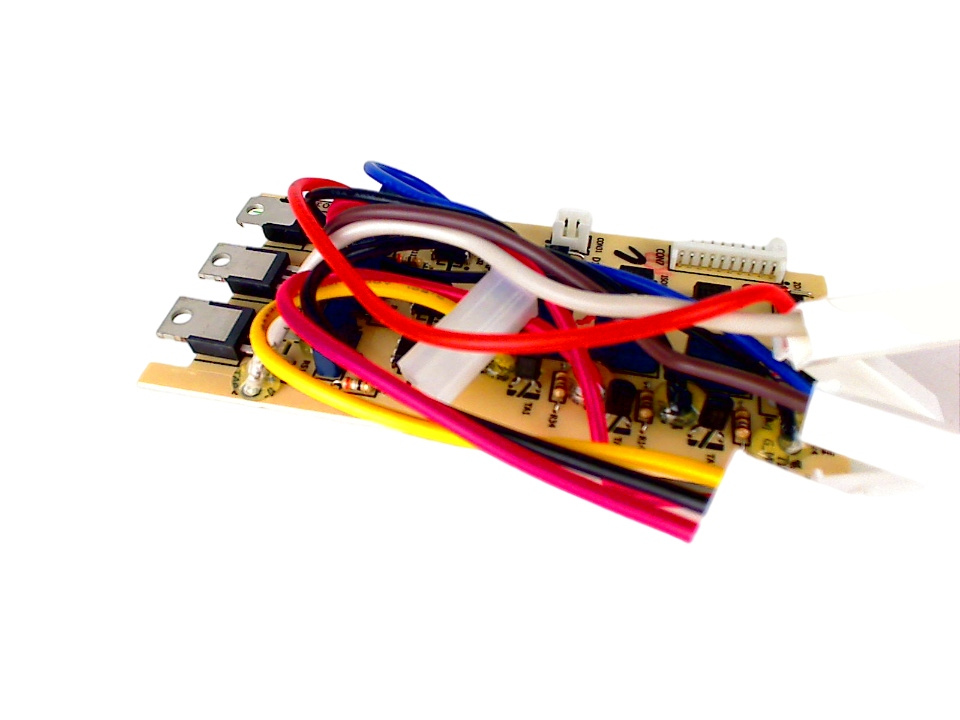

TRIAC PCB ASSEMBLY

Location Ref: 04

Exploded diagrams, Schematics and other documents

Installation

Michael

NSW

"Take off the top of the machine - two screws in the back two beside the group head, unscrew the plastic shield then unscrew the triac board. unplug the multi-strand cable from the triac board then cut the 4 coloured power cables. strip the 4 coloured wires from the new board then join crimp and insulate them with the matching coloured wires from the machine. plug the multi-strand cable into the new board. apply a small amount of thermal paste to the three sections of the heatsink and screw the triac board back in to the top of the machine. reinstall the plastic shield place the top back on the machine and test. if everything works screw the top of the machine back in place."

David

TAS

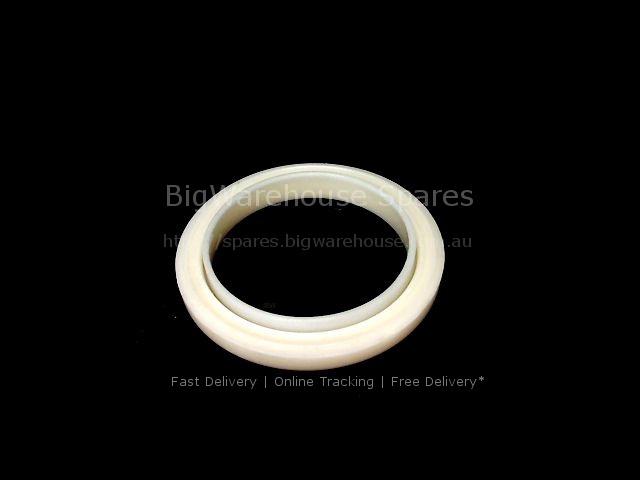

"Replacing the triac pcb assembly fixed my temperature problem. i also replaced 23 o rings (5 of which were leaking water or steam which was the root cause of the problem). info - i found the forums at coffee snobs invaluable"

Gregory

WA

"None"

David

NORTHLAND

"Triac board easy to fit providing you have the crimps needed and or can solder"

Georgina

NSW

"Na"

Scott

QLD

"Remove both back plates then two screws removed from near tamper and steam wand, remove top panel giving complete access to required circuit board, replaced circuit board"

Dmitri

VIC

"Follow instructions here httpswww.home-barista.comrepairsbreville-dual-boiler-brew-boiler-overheating-to-225-degrees-t66941.html"

Syraa

SA

"Make sure to use thermal paste when replacing the triac board"