"Aa bb"

COFFEE PUMP

Location Ref: 1.2

Exploded diagrams, Schematics and other documents

Installation

Patrick

WA

"Bes 900 pump and solenoid replacement youtube"

Bradley

QLD

"Relatively easy fix - allow approx 1 hour. remove top and back covers of machine by removing fastening screws, loosen white box at lhs rear to allow access to pump, remove pump holding screws, remove inlet-outlet tubes at base of pump and at top of pump, undo electrical press connections, remove pump, install new pump and reconnect all tubes and electrical connections tighten hold down screws remove solenoid valve from top of machine by loosening 4 hold down screws remove rubber gasket at base of solenoid valve (take care to remove the 4 small washers and 2 small flow tubes) remove any build up of crust or residual rubber with scraper andor scourer pad make sure the inletoutlet holes are not blocked with grit install new solenoid valve gasket with new washers and new flow tubes install new solenoid valve and secure with 4 screws add the flow tube. install the covers to the machine and job done."

Michael

ACT

"Youtube tutorial"

Craig

VIC

".hhhh"

Murray

HAWKES BAY

"Remove case at back, unscrew pump mounts, remove pipe clamps, remove pump, refit in reverse order."

Mark

ACT

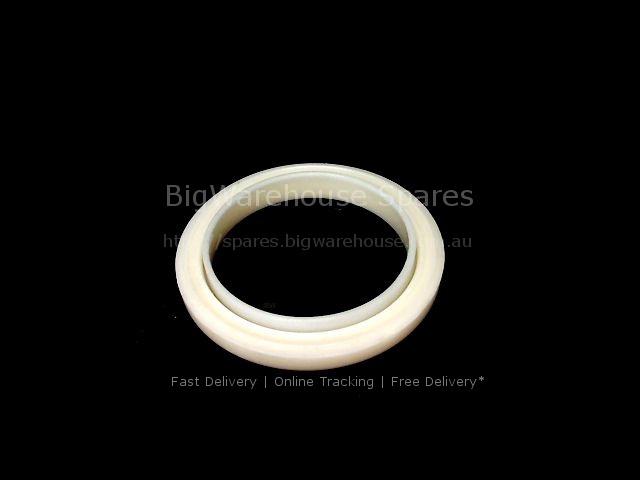

"Breville dual bes900 machine was not able to produce good pressure and was making a strange noise (which developed over time. replacement pump and solenoid arrived from big warehouse and i simply followed the instructions found on u-tube - tip: rather than cutting wires you should be able to simply unplug the pump - the fixing glue on the wires is only to hold the wires in place. take care in unscrewing the solenoid screws as they are likely to be oxidized - make sure you buy the solenoid gasket."

Adam

NSW

"Youtube"

Robert

NSW

"Original part supplied perfect fit. no need to snip wires they plug in. when refitting temp sensor fit clip from old pump to sensor before installing sensor to pump"

Adam

NSW

"Follow youtube video"