"Followed youtube clip which showed how to replace the valve on a breville bes 380"

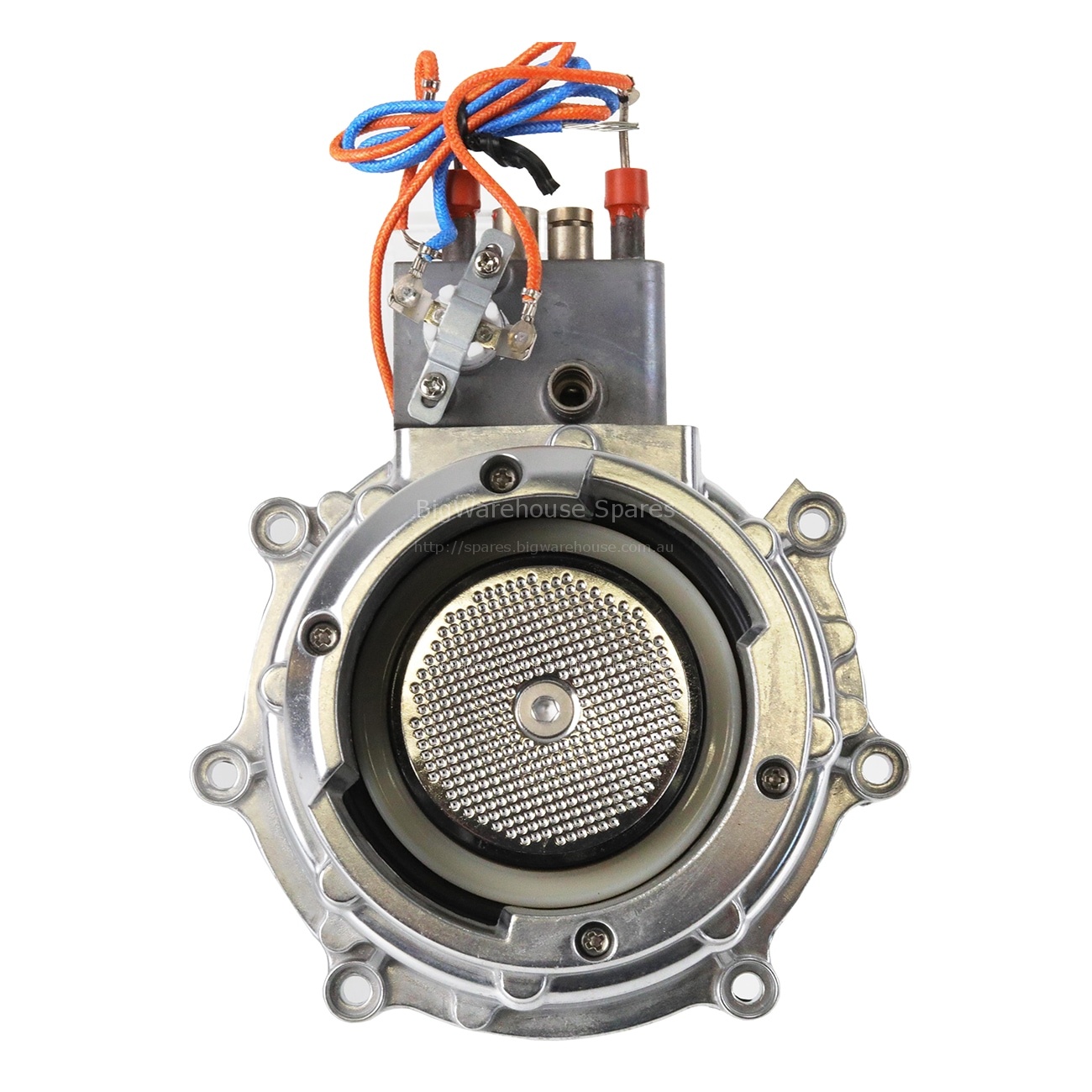

SOLENOID VALVE ASSEMBLY

Location Ref: 1.2

Exploded diagrams, Schematics and other documents

Installation

Peter

VIC

"Found how to fit on youtube"

John

CHRISTCHURCH

"Still to fit according to fittings i have seen moderate to easy.."

Bradley

QLD

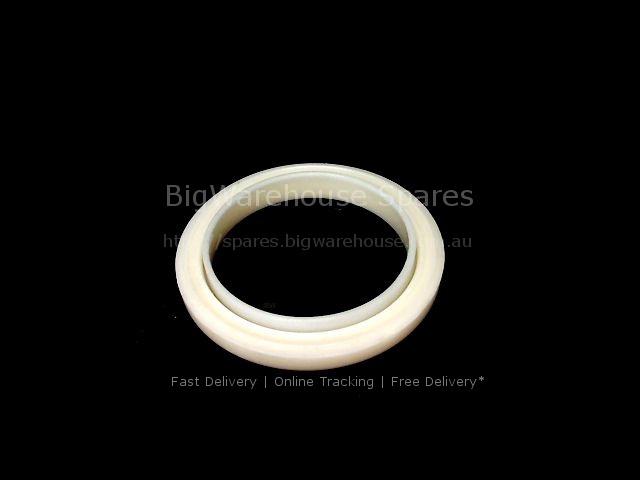

"Relatively easy fix - allow approx 1 hour. remove top and back covers of machine by removing fastening screws, loosen white box at lhs rear to allow access to pump, remove pump holding screws, remove inlet-outlet tubes at base of pump and at top of pump, undo electrical press connections, remove pump, install new pump and reconnect all tubes and electrical connections tighten hold down screws remove solenoid valve from top of machine by loosening 4 hold down screws remove rubber gasket at base of solenoid valve (take care to remove the 4 small washers and 2 small flow tubes) remove any build up of crust or residual rubber with scraper andor scourer pad make sure the inletoutlet holes are not blocked with grit install new solenoid valve gasket with new washers and new flow tubes install new solenoid valve and secure with 4 screws add the flow tube. install the covers to the machine and job done."

Decima

TAS

"Parts installed tested - made a few adjustments to set pressure again but all good"

Nathaniel

NSW

"Take cover off machine - four screws, use screwdriver then disconnect three wires, then unscrew four more screws, lift solenoid off, replace - reverse steps thats it"

David

TAS

"Replacing the triac pcb assembly fixed my temperature problem. i also replaced 23 o rings (5 of which were leaking water or steam which was the root cause of the problem). info - i found the forums at coffee snobs invaluable"

Geoff

NSW

"Installation of the solenoid is well covered by a couple of youtube videos and is pretty straightforward. youll need a phillips head screwdriver and a t15 torx screwdriver plus a small wire cutter or blade to cut a cable tie. you also need a new cable tie to replace the one youll have cut. be careful when unscrewing the solenoid because the four screws that hold it are partly obstructed by the solenoid body so the screwdriver cannot properly engage the screw head (it will be at a slight angle). it would be easy to burr the screw head if you dont engage the driver properly. new gaskets are supplied with the solenoid so dont need to be ordered separately. i couldnt believe how quiet my machine now is clearly the original solenoid was faulty from the start but not having anything to compare it to i didnt realise this until after a couple of years it became obviously wrong. the machine now is a pleasure to use."

Brian

SA

"I used a youtube video to find out how to replace the solenoid."

Mark

ACT

"Breville dual bes900 machine was not able to produce good pressure and was making a strange noise (which developed over time. replacement pump and solenoid arrived from big warehouse and i simply followed the instructions found on u-tube - tip: rather than cutting wires you should be able to simply unplug the pump - the fixing glue on the wires is only to hold the wires in place. take care in unscrewing the solenoid screws as they are likely to be oxidized - make sure you buy the solenoid gasket."